Table of Contents

Timber is one of the most beautiful and versatile building materials available, with unrivaled natural beauty and versatility. However, because it is a raw material, it is vulnerable both before and after it reaches a mill.

This covers anything from natural causes like changeable weather and insects to incorrect storage and seasoning after it’s been cut down. In today’s blog, we’ll look at the most frequent forms of wood faults and how to spot them so you can get the best timber for your home.

Common Wood Defects

Many growth features emerge in timber during or after milling. These may be considered timber faults if they have poor cosmetic characteristics or have a structural impact on the timber.

A minor mark on timber may not be structurally significant, but it will render the piece useless for joinery.

A flaw in a piece of wood may impair its structural sufficiency while improving its aesthetic attributes.

A timber flaw is an irregularity or aberration that occurs in or on wood and is responsible for its:

- Diminution in strength

- Durability decrease

- Utility cost reduction

- Appearance Issues

- Decay

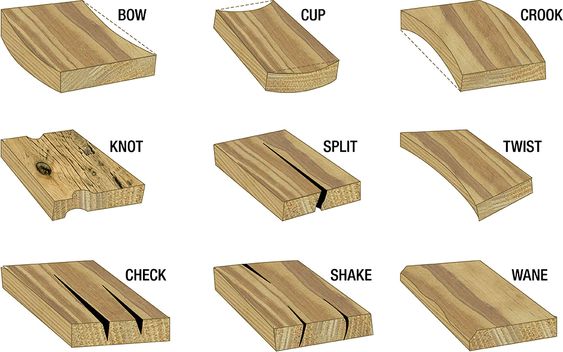

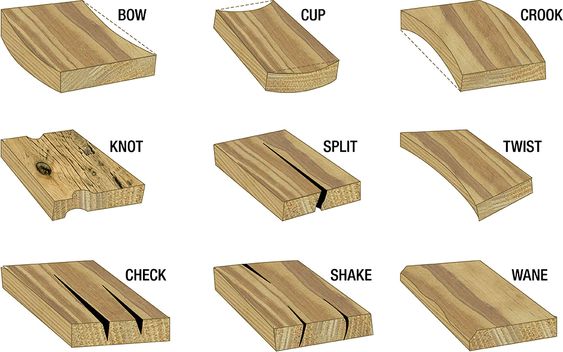

Classification of Wood Defects

Here is a list of common wood defects

- Natural Forces Defects

- Seasoning Defects

- Fungi Defects

- Conservation

- Defects due to insect

Natural Forces Defects

As one of the common wood defects, natural flaws in lumber are traits that emerge in the living tree or shortly after it is harvested that may reduce the usability of the timber. It is frequently more cost-effective to eliminate faults such as dead knots and replace them with plugs.

Here is a list of wood defects due to Natural forces:

Chemical Stain – The wood is sometimes discolored as a result of chemical action caused by an external agent. This is referred to as a chemical stain.

Rind Galls – The rind represents Bark, and the gall represents abnormal growth. Rind Gall refers to a peculiarly curved swelling found on the body of the tree. They form where branches have been improperly cut off or removed. They are rarely found in trees, and the timber in this section is very weak and not long-lasting.

Coarse Grain – When a tree grows quickly, the annual rings become wider. It is known as coarse-grain timber, and it has less strength.

Knots are the end sections of branches where that grow out of the trunk. Knots can be considered as being either live knots (i.e. knots that are firm in their socket and show no signs of decay, also known as sound or tight knots) or dead knots (i.e. knots that are separated from the surrounding signs of decay).

Deadwood – Deadwood is present in timber harvested from dead-standing trees. It is distinguished by its lightweight and a reddish hue.

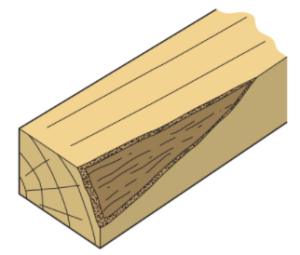

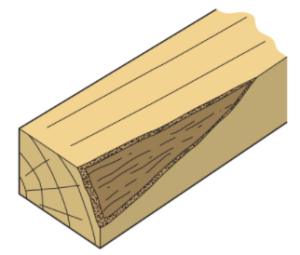

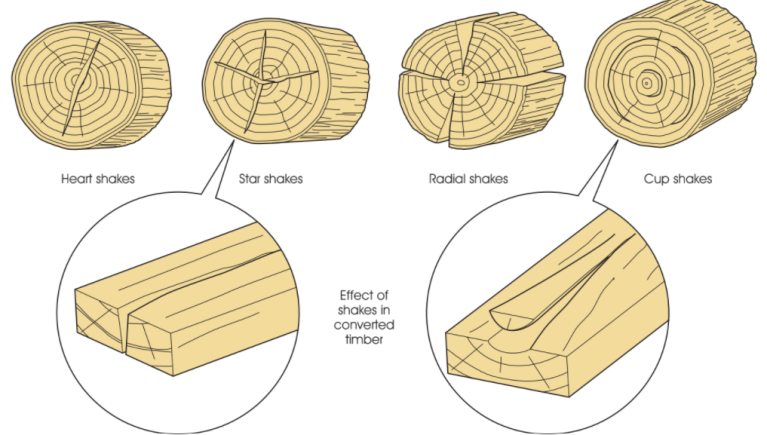

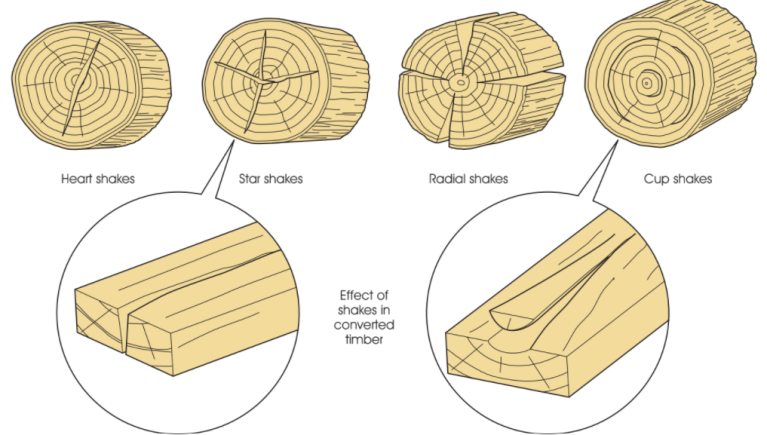

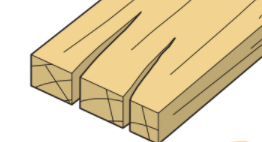

Shakes are caused by a separation of the wood fibers along the grain developed in the standing tree, on felling, or prior to seasoning. The shake is formed as a result of stress relief, causing a longitudinal crack radiating from the heart and spreading through the diameter of the trunk.

Types of Shakes:

- Heart shakes are cracks along the heart of a tree and are probably due to over-maturity.

- Star shakes are number of heart shakes that form an approximate star.

- Radial shakes are cracks along the outside of the log and are caused by the too-rapid natural drying of the outside of the log before it is converted or by heavy felling onto hard ground.

- Cup shakes or ring shakes are a separation between the annual rings and are normally the result of a lack of nutriment. It is also said to be caused by the rising sap freezing during early spring cold spells.

Seasoning Defects

Another common wood defects where occurs during the drying process. Controlling the rate and degree of drying requires extreme caution.

Many newly cut timbers contain more than half of their weight in moisture or sap. Seasoning is merely the process of drying out timber so that it is conditioned (or pre-shrunk) before use.

Seasoning decreases the moisture content of the wood to that of the atmosphere’s relative humidity.

Moisture content in equilibrium. Shrinkage is unavoidable during drying, and every effort is made to minimize distortion and splitting.

Seasoning defects can be further divided into:

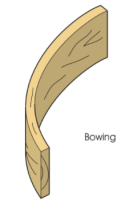

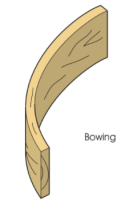

Bowing is a curvature along the face of a board, and often occurs where insufficient piling sticks are used during seasoning.

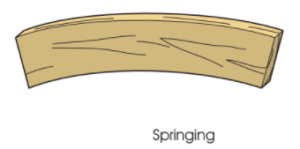

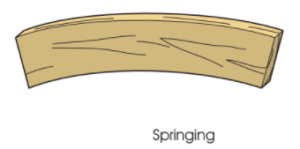

Springing is a curvature along the edge of the board where the face remains flat. It is often caused by bad conversion or curved grain.

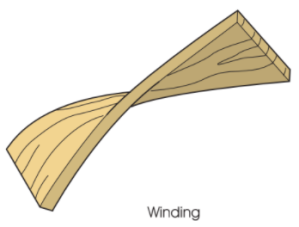

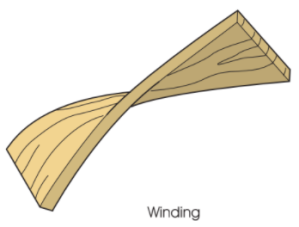

Winding is a twisting of the board and often occurs in wood that is not converted parallel to the pith of the tree.

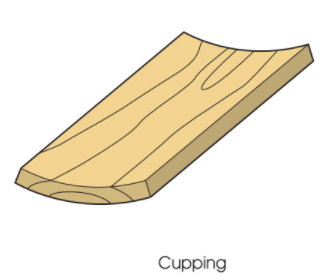

Cupping is a curvature across the width of the board and is due to the fact that wood shrinks more tangentially than it does radially.

Case Hardening – These are fissures (separation of wood fiber) that develop along the grain of a piece of wood, particularly at its ends, and are the result of the surface or ends of the wood drying out too fast during seasoning. The term ‘fissure’ also includes resin pockets when they appear on the face or edge of a board.

Fungi Defects

Blue Stain – fungi cause the sap of wood to turn a bluish color.

Brown Rot – fungi remove cellulose compounds from wood, causing the wood to turn brown.

White Rot – It is the polar opposite of brown rot. In this type of fungi attack, wood lignin takes on the appearance of a white mass composed of cellulose compounds.

Wet Rot – fungi cause the chemical decomposition of wood timber, transforming it into a greyish-brown powder. It is referred to as wet rot. Some key points to remember about wet rot are as follows.

Dry Rot – fungi feed on wood and convert it into a dry powder. This is referred to as dry rot. The following details should be noted. Dry rot occurs in places where there is no free circulation of air, such as poorly ventilated basements, rooms, and so on, as well as in damp conditions, such as kitchen toilets.

Heart Rot – When exposed to atmospheric agents, heartwood weakens and produces an out hollow sound when struck with a hammer.

Defects due to Conservation

This is one of the most common wood defects, and if certain conditions are not met during preservation, the preserved wood will suffer from these effects.

Chip Mark Indicated – Chip marks are marks or signs left by chips on the finished surface of the timber.

The Diagonal Grain – These defects in timber are caused by improper timber sawing. It is denoted by diagonal marks on the timber’s straight-grained surface.

The Torn Grain – These timber defects occur when falling timber creates a small depression on the finished surface of the timber.

Wane – The presence of the original rounded surface on the manufactured piece of timber indicates this.

Defects Due to Insects

In terms of insect attack, termites are the most dangerous to structural timbers. Most timbers are attacked in the sapwood and heartwood. However, sapwood and pith are preferred.

Lives in the colony and is very fast at eating away the wood from the cross-core. section’s

Makes tunnels in various directions without disturbing the outer shell or cover.

Few good timbers, such as Teak, Sal, and others, can withstand termite attacks.

Some Australian timbers are resistant to termite attack due to their cellular structure i.e.

- Cypress pine

- Jarrah

- Grey Ironbark

- Red Gum

- Tallowwood

- Turpentine

Termites are of two wide species

- Subterranean species are those that live beneath the ground.

- Dry wood species are found in timber above ground.

Dry wood species are wood-dwelling organisms that can survive in seasoned timber with low moisture content. Colonies can be found in and between wood members, such as a wall frame or a tree branch.

Subterranean termites prefer darkness and avoid light, so they travel inside tunnels. Metal and caps used on top of piers and walls will not prevent termite infestation, but they will draw attention to it as they build out over the angled metal. Creosote is a termite repellent, but it must be applied to the ends of the timber.

Treatment can be done after construction, but it is obviously easier to do it during construction. Mechanical prevention methods such as Granit Gard, Termtimes, and TERMISHIELS are common today. Spraying is no longer practiced.

Defects Caused By Beetles

They live in salty water. They dig tunnels or boreholes to find refuge. The diameter and length of the holes can reach 25MM and 60MM, respectively. Wood that has been affected loses its color and strength. No wood is completely impervious to the attack of marine borers.

The beetle lays its eggs in wood cracks and crevices. These eggs hatch into small worms that burrow into wood. For up to two years, they eat their way through the wood. The worms then transform into beetles and exit through a woodworm hole.

As a result, woodworm can affect wood for a long time before the woodworm holes are visible. The beetles are about the size of a pinhead and are light brown in color. They are most active during the summer months when they fly around and lay their eggs on furniture. They are particularly fond of the plywood backs of cabinets. Although there is little that can be done about the worms in the wood, there are several products on the market that poison the beetles as they emerge and destroy any eggs laid” on the surface.

FAQs

What are the different types of timber defects?

1. Natural Forces Defects

2. Seasoning Defects

3. Fungi Defects

4. Conservation

5. Defects due to insect