Table of Contents

Introduction to Epoxy Floor

Epoxy floors are a common flooring choice in commercial and industrial work environments due to their wide range of appealing qualities. The principles and subtleties of epoxy floors could be unclear, nevertheless, due to how complicated the subject of resin flooring can be.

The flooring experts at Flowcrete are here to help. We’ve prepared a quick overview of epoxy flooring, a list of the most prevalent types of epoxy floors, a list of the benefits of epoxy as a flooring system, and other helpful details.

Firstly, What is Epoxy Flooring?

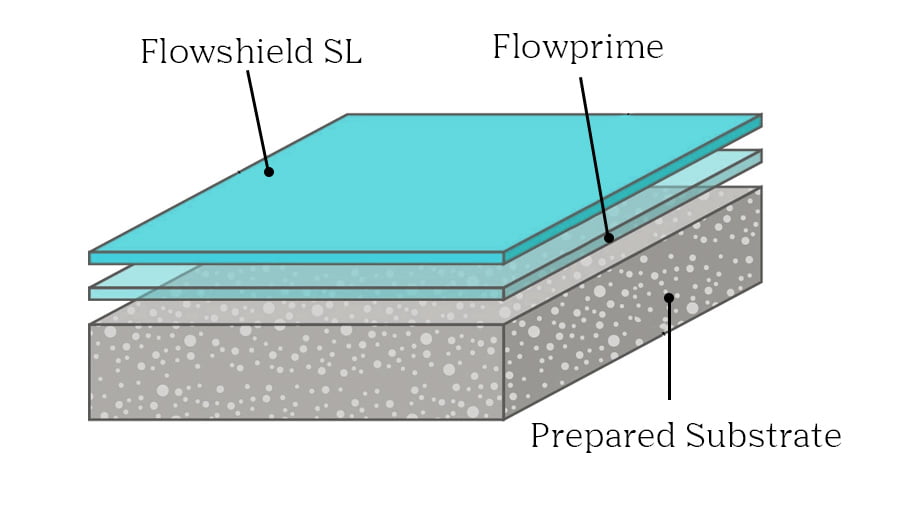

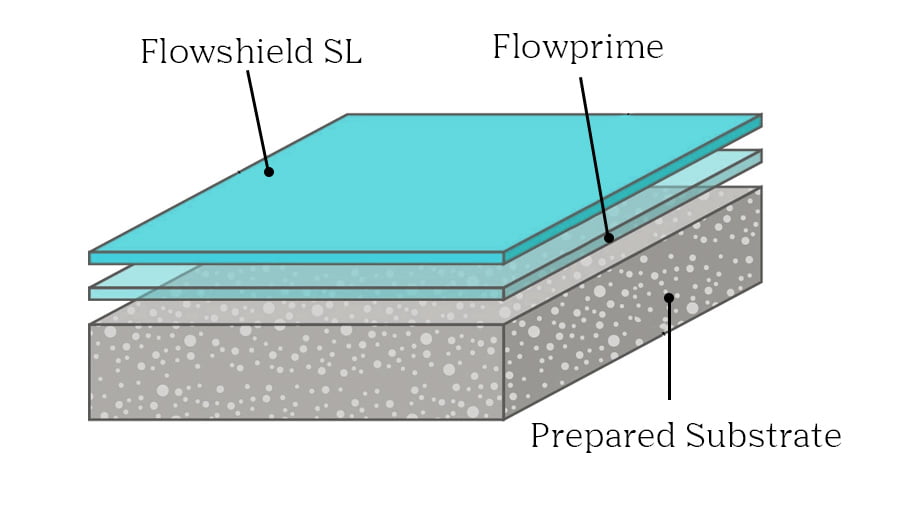

Epoxy flooring, in a nutshell, is a type of artificial resin floor system that is applied on top of concrete substrates as a form of protection and decoration. The techniques typically include coating, troweling, or pouring many layers of thermosetting resin over a concrete substrate. The floor system creates a solid and long-lasting bond after the resin layers are fully cured, acting as an impenetrable and aesthetically pleasing barrier to shield the substrate.

Due to its excellent mechanical and chemical resistant qualities, epoxy is most likely the most well-known resin floor technology. Additionally, a variety of colors, designs, effects, and decorative alternatives can be added to epoxy flooring.

Epoxy flooring systems come in a variety of categories, though, to suit various uses. When flooring words are used synonymously, for example, coating = flooring = screed, confusion might result. Technically speaking, this is incorrect because each term has a unique profile and set of attributes.

Types Of Epoxy Flooring

Epoxy floors are smooth, incredibly adaptable, and may be manufactured in a variety of colors, designs, effects, and ornamental alternatives. They are appropriate for use in industrial and commercial settings thanks to these qualities. There are a number of standard varieties of epoxy flooring, including:

- Epoxy Terrazzo Flooring

- Epoxy Flake Coating

- Epoxy Floor Coatings

- Epoxy Self-Levellers

- Antistatic Epoxy Flooring

- Epoxy Screeds

Epoxy Terrazzo Flooring

Epoxy terrazzo flooring offers a seamless, vibrant, ornamental, and long-lasting flooring surface. This kind of flooring is made from a combination of colored epoxy and certain particles (such as marble, mother of pearl, glass, granite, etc). Following the mixture’s setting, the floor is ground and polished, revealing the aggregate and producing a smooth, aesthetically pleasing, and durable floor finish.

Not only are epoxy terrazzo floors extremely durable and aesthetically pleasing, but they also require very little upkeep and have a very long lifespan (upwards of 40 years). Large commercial venues benefit greatly from this floor system’s beauty, longevity, and durability.

Epoxy Flake Coating

Epoxy flake coatings are made by sprinkling different-sized flakes over a colored epoxy base coat and then sealing it with a robust, durable clear sealant. It creates a beautiful floor finish that is simple to maintain and offers exceptional abrasion and chemical resistance.

Among many other business locations, shops, showrooms, restaurants, and schools are excellent candidates for epoxy flake coating.

Epoxy Floor Coatings

Epoxy paint or epoxy floor paint are other names for epoxy floor coatings. The finishes often come in a single uniform color, with the option of matte, satin, or glossy finishing. Epoxy floor coatings are typically employed in industrial or commercial settings with modest to moderate activity levels.

To get the flooring that is best suited for your needs given the extensive variety of epoxy coating kinds and alternatives, consult a flooring expert. There would be an appropriate flooring option accessible to match the needs, depending on the environment’s goals and functions.

Epoxy Self-Levellers

Epoxy flooring with self-leveling (SL) capabilities has the ability to self-smooth after being applied to a surface. Self-leveling systems typically have a thickness of 1 to 3 mm, are installed quickly using liquid application, and have a smooth, seamless finish. Epoxy SL compositions that are resin-rich offer an extremely strong, long-lasting finish for demanding, heavy-duty settings.

Antistatic Epoxy Flooring

A smooth, durable coating called antistatic epoxy flooring prevents electrostatic charge from building up on the floor’s surface.

Antistatic floor systems are intended to securely transmit the static charge that can be generated by a person to designated earthing points and should comply with antistatic standards criteria (e.g., ANSI/ESDS2020, IEC 61340-4-1). For light, medium, and heavy traffic, there are various antistatic flooring technologies designed for each.

Epoxy flooring that resists static electricity is frequently utilized in clean rooms, laboratories, and specialized food processing facilities. It is frequently utilized in the electronic, aerospace, automotive, and pharmaceutical industries as part of ESD (Electrostatic Discharge) protection in situations holding sensitive equipment or explosive substances.

Epoxy Screeds

Epoxy screeds are a standard heavy-duty underlayment for receiving a variety of resin flooring and are a component of a medium- to heavy-duty flooring system (such as anti-slip coatings, self-levelling epoxy coatings, etc). The typical thickness of an epoxy screed, a thicker kind of flooring layer, is 4 to 6 mm. Epoxy screeds must typically be troweled on since they are thicker, and they can also be power floated to create a smooth, level finish.

Epoxy screeds have great impact resistance and strong strength. The epoxy screed may also have anti-osmosis qualities to function as a damp-proof membrane.

Epoxy screeds are perfect for flooring systems in medium- to heavy-duty industrial settings, including manufacturing, food and beverage processing, and a variety of other industries.

The expected functions and protection requirements based on the regular activities and operations of the facility influence the specification/selection process of epoxy flooring.

Epoxy Flooring Advantages and Benefits

Let’s examine the particular advantages and benefits of epoxy flooring. Comparing epoxy flooring to other floor coverings like vinyl, tiles, or carpet reveals various advantages and benefits.

Aesthetics

Epoxy flooring comes in a wide range of customisable colors and gloss levels, and it can be installed as a smooth, simple-to-clean floor surface (glossy, satin, matte). Colored microchips and metallic pigment additions are additional design alternatives.

Maintenance

The concrete substrate is shielded from chemicals, dirt, liquids, and other impurities because epoxy is a smooth and impervious flooring solution. Because of this, cleaning the floors is simple and doesn’t require waxing or polishing; instead, just a basic mop and a general-purpose cleaner will do. Epoxy flooring are a fantastic long-term value option because they only need a routine cleaning and minimal upkeep.

Durability

Truck and forklift traffic can be as heavy as foot traffic, and epoxy floors can also handle both. Industrial flooring options can resist regular assault from a variety of machinery and production techniques. Epoxy flooring alternatives can satisfy the durability requirements of the majority of industrial producers as they are an abrasion and chemical-resistant substance.

Safety

Epoxy flooring has the possibility to incorporate a non-slip profile by sprinkling sand on the wet body coat while being applied, which is one of its less-noticed benefits. This is a crucial component for commercial or industrial buildings because people’s safety should always come first.

Environment Suitability

Epoxy flooring is one of the most adaptable types of flooring and works well in a wide range of settings, including commercial, industrial, medical, food and beverage manufacturing, aviation, recreational, healthcare, transportation, manufacturing, educational, grocery, and retail establishments, among others.

Disadvantages and Drawbacks Of Epoxy Flooring

Although there are many advantages to installing epoxy flooring, it’s crucial to be aware of any potential drawbacks.

Slippery Surface

When they are wet, epoxy floor coverings can be highly slick. If there can be spills or water on the floor, the epoxy floor is not a good option. You must add texture to the floor with add-in materials to make the surface less slick.

Adherence Difficulties

The material does not adhere well in a damp environment, including a cellar. When the basement floor is dry and ready before pouring the epoxy, adhesion problems can be prevented. The epoxy paint lifts off the floor when it is applied in a damp environment to a wet surface.

Drying Process

Epoxy floors often take longer to cure than other types of flooring do. Prior to real use, a floor must be given the chance to completely dry out.

Smell

Standard epoxy flooring has a tendency to smell chemically as it dries. Epoxy flooring vapor exposure carries some risk.

Although the off-gassing won’t last as long as it would with other types of flooring if you give the floor enough time to dry.

A Final Note:

Epoxy flooring are a fantastic alternative for a range of industrial and commercial settings because they combine performance and aesthetics. Different flooring options from Flowcrete are suitable for various work conditions and each has its own advantages. If you have a flooring project that would benefit from our flooring knowledge, let us know.

FAQs:

What Is Epoxy Flooring?

Epoxy flooring, in a nutshell, is a type of artificial resin floor system that is applied on top of concrete substrates as a form of protection and decoration.

What are the Types Of Epoxy Flooring?

– Epoxy Terrazzo Flooring

– Epoxy Flake Coating

– Epoxy Floor Coatings

– Epoxy Self-Levellers

– Antistatic Epoxy Flooring

– Epoxy Screeds